Little Known Facts About Waterproofing Auckland.

Wiki Article

Everything about Waterproofing Auckland

Table of Contents10 Easy Facts About Waterproofing Auckland ShownThe Buzz on Waterproofing AucklandWaterproofing Auckland for BeginnersSome Known Incorrect Statements About Waterproofing Auckland Some Ideas on Waterproofing Auckland You Should Know

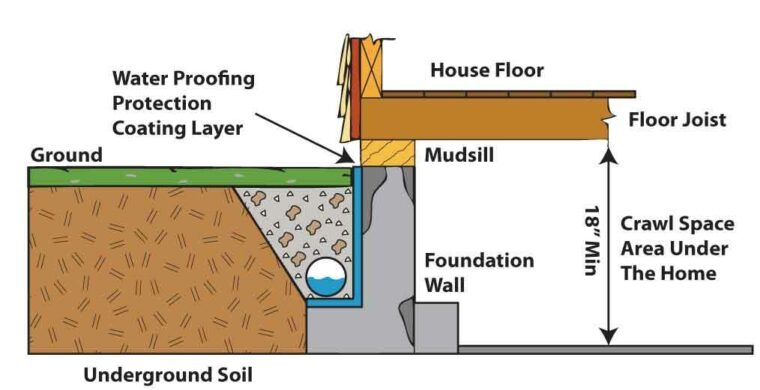

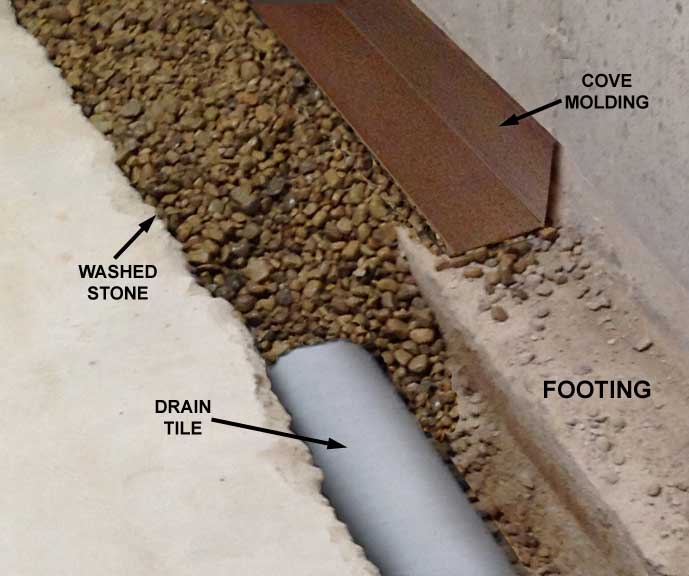

45m (18) in size, are laid in progressive slopes. The joints of these pipelines are maintained open. The gathering chambers are constructed at suitable periods as well as at turning factors. The gathering chambers are not glued from the within or outdoors, to receive water from the environments. The perforated pipelines are then covered with loosened materials like chips and steel, to develop a filter media.The below ground water discovers the means of least resistance through the filter media. The water is accumulated in the perforated pipes with the filter media.

The procedure for the below ground water tank coincides as that of the basement, other than for the following points. A stipulation for a pump sump is made, as opposed to the seamless gutter setup. The overflow pipeline is situated at the wanted level, to drain pipes out the excess water. Examine this pipe for its tightness before the waterproofing work procedure.

Some Known Details About Waterproofing Auckland

If white or tinted joints are required, then the grey concrete joints are raked, and also white cement or shade concrete slurry is used with a tiny travel over the surface area for joints of a matching shade. The surface area is again cleansed with sawdust. to get rid of excess white or color cement adhering to the polished china mosaic surface area.Bonus product is reduced off with a putty blade and a smooth upright joint is produced. Because the sealant is extremely costly, use it.

The outermost surface of the sealant should present a somewhat concave surface in profile. Eliminate the masking tape as well as tidy the surface with suitable solvents. For water-proofing of the straight growth joint, arrangements ought to begin from the R.C.C. phase of the building. The adhering to procedure should be observed. Upside down beams are taken to the place, for the development joint, alongside.

Socketing (pressure grouting)' is a treatment to grout the concrete slurry by stress right into the permeable concrete participant. Adhering to a series of the job treatment.

4 Simple Techniques For Waterproofing Auckland

Deal With 25mm (1) G.I. outlet over the metal, making use of rich concrete mortar around the socket and also metal. If the waterproofing job procedure is not done properly, it can present problems. Fixings and upkeep of waterproofing can show really problematic for the customer.is where the maximum water is made use of. Normally, the moms and dad slab of the W.C. device has an I.W.C. Pan as well as a concrete case of size 0. 9m x 1. 2m x 0. 6m. This instance is water-proofed after repairing the essential accessories such as P-trap, C.I. item, W.C. frying pan, etc system can show the different factors of leakages, as listed here. The joint between the C. 1/P. V.C. piece and also P trap. The joint in between the (tee) of outer vertical pile as well as P.V.C./ C.I. item. The joint between the P-trap and I.W.C. pan. The joint in between the flushing pipeline and I.W.C pan. All these joints need to be secured with the proper sealant, at the corresponding stages during the execution of the job.

Examine the joint in between the P-trap and also L.W.C. frying pan from above, by putting a hand right into the catch. Inspect the joint between the flushing pipe and L.W.C. pan by damaging just one ceramic tile, fitted precisely over the junction.

Not known Incorrect Statements About Waterproofing Auckland

Open up the "Tee' of the vertical pile from the outside, with a ladder or zula and observe the joint of C.I. item as well as Tee' with torchlight and seal it correctly. If leak still continues, burst the hidden flushing G.I. pipe and examine if it is leak-proof. Replace the dripping pipe/G. I.

If this does not stop the leakage, break open the complete device as well as check the joint at the P-trap as well as C.I./ P.V.C. pipeline. Do the new waterproofing job procedure entirely with utmost care. Usually, 90% of leakages quit, if we execute the repair as specified over, in the very first see this page 4 points.

This can be checked by quiting the procedure of the wash hand container as well as keeping these lines entirely dry and also running them again after 4-5 days. If the leaks completely dry out as well as start, the resource is with these lines.

If leaks still continue, attempt socketing as well as grouting of cement slurry in the afflicted section. Damage open the washroom waterproofing job treatment and also re-do it carefully. A typical and also successful method for dealing with minor leakages is to treat the afflicted part with concrete slurry. Apply the concrete slurry from the leading and also let it penetrate in the cracks with the top part.

The Main Principles Of Waterproofing Auckland

Examine the afflicted portion of the terrace using a wood mallet and also check if it has actually Source peeled off. If the leakage is from the edges or from the parapet wall, after that fill all the fractures after breaking it open with concrete.Some chemicals are recommended for blending with cement, at the time of concreting. The standard method of brickbat coba is still one of the most popular of water-proofing approach in India. Waterproofing compounds are usually available in powder and also liquid type, as they offer the dual objective of waterproofing work procedure and also warm shielding.

Guarantee that the socketing is done prior to the skim coat work. Make certain that there is no leakage from the bathroom W.C. piece once the socketing is done. Ensure that the catches and also release pipes are dealt More about the author with appropriately prior to the brickbat coba layer. Make sure that all the brickbats are well-soaked in water, prior to use.

Maintain an appropriate space in between the brickbats. Check the slope of the brickbat coat, in the direction of the catch. Make certain that the water-proofing compound is mixed in the mortar, for each phase of job. The overcoat should be carried out in one stroke, without any type of joints. Make certain correct finishing near traps as well as spouts.

Report this wiki page